The fluid control leader that defines the history of chemical pump development and progress and produces many types of pumps in small quantities

A very large selection of pumps and other products is what defines IWAKI most of all. For more than half a century, we have created products that reflect a diverse array of customer requirements. A production system capable of making many types of pumps in small quantities is vital to meeting these requirements. Many of our customers tell us that they always contact us first whenever there is a need involving a pump. Our history is also the history of advances in chemical pump technologies and we are proud of our leading position in this industry. Backed by quality assurance and manufacturing skills resulting from many years of experience and accomplishments, we are dedicated to supplying high quality products that always meet our customers’ expectations.

IWAKI covers all areas of Japan with its head office and branch and sales offices in 13 major cities. This network along with relationships with sales agents nationwide result in the rapid provision of services to customers. Outside Japan, IWAKI has a global sales and service network consisting of 19 group companies in 15 countries. We supply fluid control products for almost every industry as an organization operating on a global scale. One competitive advantage is the reputation of a company based in Japan as a supplier of products that are safe and rugged. We have a firm commitment to creating our own safety mechanisms and making products with outstanding durability in order to meet our customers’ needs.

IWAKI has been developing and manufacturing chemical pumps and other fluid control products since its establishment in 1956. We are the oldest company in this industry as well as the most advanced. We are constantly using the latest technologies to supply products incorporating new concepts. We will continue to meet a diverse array of our customers’ requirements by leveraging knowledge acquired over our many years of operations.

Many of our products are made for specific customers. In our 60 series of products, we have thousands of models. The ability to manufacture large numbers of different products in small numbers is one of our greatest strengths. Although we make many low-volume items, our annual output is more than 600,000 units, ranking us first in our industry. This large-scale production capacity combined with a large selection to meet almost any customer need is a major reason that IWAKI is recognized as the world’s preeminent manufacturer of fluid control products.

We are constantly seeking ways to make more improvements regarding the safety, quality and durability of our products. We have created our own safety mechanisms and developed many high-end products that utilize the latest advances in electronics technologies. Our goal is to continue to supply products with even better performance in relation to cost that customers can use with confidence for a long time.

IWAKI has a global sales and service network with 19 companies in 15 countries.

In Japan, branch offices and sales offices in 13 major cities work closely with sales agents to provide customers with speedy services.

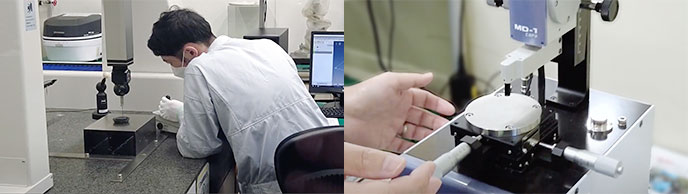

Customers always demand the highest levels of safety in the fluid control products they use. In addition to ensuring obvious attributes like no leaks or malfunctions, we must fabricate products with the extreme precision required by each application. To create products that meet customers’ requirements, we place emphasis on research and development activities. Furthermore, we are continuously upgrading our technologies in order to supply high-quality products that comply with our own rigorous internal standards.

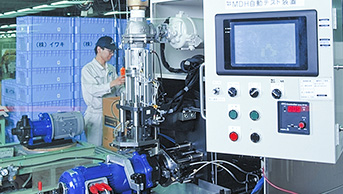

Technology departments work with sales departments in order to utilize customer feedback for supplying products that are even better, even less expensive, and can be launched even faster. Fluid control products must deliver the best possible performance under a variety of conditions, such as the volume and pressure of fluid, precision, temperature, absence of pulsation and other characteristics. This is why we start selling a new product only after long hours of repeated testing under actual-use conditions.

As a leading manufacturer of fluid control products, we are constantly upgrading our R&D capabilities involving technologies. At IWAKI, more than 20% of employees are assigned to jobs in departments involving technology in order to create new technologies and products. To provide the extremely difficult and complex fluid control performance demanded by customers, our R&D activities target the creation of next-generation pumps and systems that quickly incorporate the latest technologies.

Our capabilities involving technologies have been vital to our ability to remain at the forefront of our industry. We have created ideas for the use of our pumps and fluid control products in the production processes of a broad spectrum of industries: semiconductor and liquid crystal products, surface treatment equipment, water treatment, food, paper, pharmaceuticals, and many more. Please contact IWAKI first about the use of this large and diverse product lineup to meet a requirement involving pumps and fluid control.

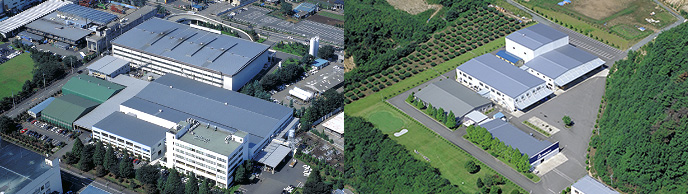

We believe that all production processes are also quality control processes. The Saitama and Miharu plants make this thinking an integral part of their manufacturing activities. We have a quality assurance system that complies with ISO9001 and use this system for every step from procurement to manufacturing and shipments to customers. At the inspection stage, we use sophisticated measuring instruments and testing equipment with the goal of zero defects. This quality assurance system is a major reason for our confidence in our ability to consistently manufacture products that have outstanding quality.

IWAKI received ISO9001 certification for quality assurance systems in 1996. We are always reexamining key design and production processes to seek ways to further improve quality and to optimize and streamline these processes. In 2005, we received ISO14001 certification for environmental management systems and have many activities to reduce the environmental impact of our business operations.

The Saitama and Miharu plants supply our products to customers

worldwide under our own strict management systems that comply with

ISO9001 and ISO14001. Large process pumps are the main product of the

Saitama plant. The Miharu plant manufactures large volumes of compact

products including the MD series of magnetic drive pumps, our

best-selling product.

Every step of all production lines is

thoroughly checked in order to ensure that our operations benefit our

customers and society with regard to both quality and protecting the

environment.

IWAKI uses the cell production method in which every step from assembly to packaging takes place in a single booth. Using this system better allows us to produce many products in small numbers. There are also exacting inspections beginning with the receipt of components. 3D measuring devices examine components with intricate shapes, x-ray analysis is used to confirm no violations regarding chemicals in our products, and many other tests are performed. We are always aiming to be first to use the latest advances in testing and inspection equipment. Furthermore, we are continuously improving production systems and work flows in order to ensure that we supply products with outstanding quality.